- Write by:

-

Wednesday, November 15, 2023 - 18:17:10

-

100 Visit

-

Print

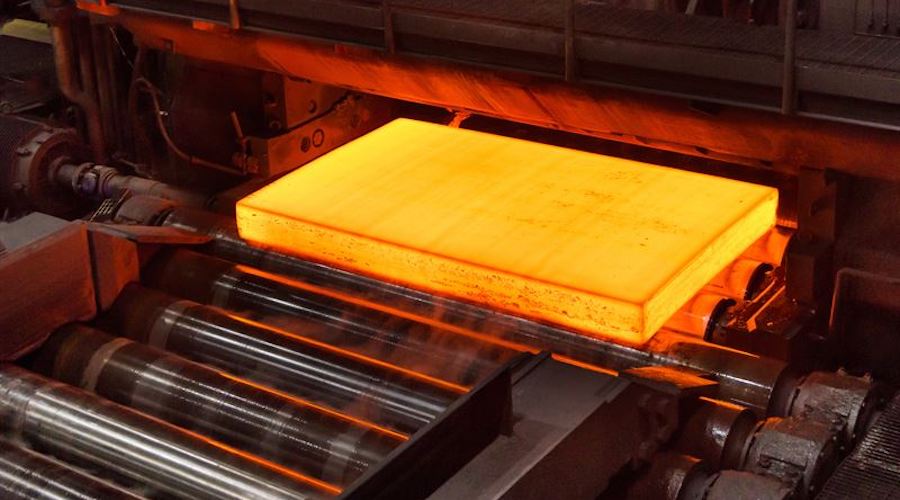

Mining News Pro - Electrical equipment multinational ABB released a report spotlighting three initiatives that are using carbon capture technology, hydrogen and electrochemistry as routes to decarbonizing primary steel production.

According to the report, Brazil, China, India, Sweden and the US are the countries leading the way towards fossil-free steel, a key element of the United Nations Paris Agreement on climate change. The deal asks for limiting global temperature increase to below 1.5 °C compared with pre-industrial levels, a goal that implies that the steel industry must achieve a target of net zero emissions by 2050.

At present, steel production is considered one of the six ‘hard to abate’ sectors. Globally, it is responsible for an estimated 8% of the world’s energy demand and generates between 7% to 9% of CO₂ emissions – most of which are from burning fossil fuels, according to various sources including the recent International Energy Agency Iron and Steel Technology Roadmap.

Among the initiatives working towards addressing the issue are the Hydrogen Breakthrough Ironmaking Technology (HYBRIT), piloted in Sweden by steelmaker SSAB, state-owned iron ore miner LKAB, and state-owned energy company Vattenfall to make steel using green hydrogen and fossil-free electricity using the high-grade iron ore from the LKAB mines instead of coking coal.

The report also highlights the work conducted by the ResponsibleSteel industry association-backed Aperam, which has interests in stainless steel and agriculture and focuses on the use of charcoal produced from its own 100,000 hectares of FSC-certified forests in Brazil as a renewable substitute for coal-based coke in steelmaking to significantly reduce CO₂ and entirely eradicate the use of extractive coal.

Finally, the HIsarna process by Tata Steel in India, which uses a powdered form of the raw ore material instead of processed ores such as coke, sinter or pellets to make liquid pig iron, is praised as it can reduce emissions by up to 20% compared with the traditional Blast Furnace-Basic Oxygen Furnace (BF-BOF) method.

“Regulatory, commercial, and social drivers are accelerating the journey to decarbonize steel,” Frederik Esterhuizen, global business line manager for metals at ABB, said in a media statement.

“But to address the core challenges set out in ABB’s report and phase out fossil fuels, the steel industry will need powerful, integrated solutions and must collaborate at every level of the global steel supply chain in order to succeed.”

Short Link:

https://www.miningnews.ir/En/News/627665

Anglo American Plc said it is has received an unsolicited non-binding combination proposal from BHP Group.

Australia’s Fortescue on Wednesday logged a larger-than-expected decline in third-quarter iron ore shipments, following ...

Iron ore futures prices ticked lower on Monday, weighed down by diminishing hopes of more stimulus in top consumer ...

Iron ore futures prices drifted higher on Thursday as the latest soft data from top consumer China triggered renewed ...

Vitol Group confirmed that it’s starting to rebuild a trading book for metals after a long stint out of the market, with ...

Australia’s Fortescue said on Monday it would form a joint venture with OCP Group to supply green hydrogen, ammonia and ...

Iron ore reversed direction after dropping to its lowest level in 10 months as optimism that the country’s economic ...

Iron ore reversed direction after dropping to its lowest level in 10 months as optimism that the country’s economic ...

Nippon Steel intends to pursue its proposed acquisition of US Steel and wants its “deep roots” in the United States to ...

No comments have been posted yet ...