- Write by:

-

Tuesday, August 3, 2021 - 13:52:41

-

503 Visit

-

Print

Mining News Pro - BHP has set itself to expand production by 40 per cent at its Mount Keith nickel mine in Western Australia, with a new semi-autogenous grinding (SAG) mill, flotation technology and two new Liebherr excavators.

Speaking at the 2021 Diggers & Dealers forum, BHP Nickel West asset president Eddy Haegel said BHP was looking to respond to an increase in nickel demand at Mount Keith.

“Nickel West’s future is very positive – and the opportunity to grow is real, as demand for future facing commodities like nickel is likely to get stronger,” Haegel said,

Haegel last spoke at the forum in 2017, when he said BHP would need to transition from stainless steel to nickel.

In 2021, he confirmed BHP had made the right call.

“We discovered that unlike stainless steel, Nickel West was remarkably well positioned to support the emerging battery sector,” Haegel said.

“We discovered that nickel is the most important metal to produce high-intensity batteries for electric cars and that we are one of the leading nickel powder producers – a product that remains one of the lowest cost pathways to producing nickel sulphate.”

To facilitate the transition and consolidate its place as one of the world’s most sustainable nickel producers, the Mount Keith operation is expanding to a 15 million tonne per annum (Mtpa) operation.

“The Mount Keith concentrator expansion will involve installing a third and much larger 16 megawatt SAG. Together with the modernisation of the flotation circuit, we will increase the concentrator from 10.5Mtpa, to 12Mtpa, and eventually 15Mtpa,” he said.

“The SAG has been ordered from Metso Outotec as a pre-commitment, as the project completes the final detailed design stage, before execution approval at the end of the financial year.”

BHP will look at a new flotation circuit which looks to increase recovery of ultrafine nickel particles using Concorde cells from Metso Outotec.

Haegel explained that “Concorde cells use high pressure flows of slurry into an impact zone to force the bubbles and particles to attach.”

BHP will also install a flash flotation circuit at Mount Keith, with both new circuits expected to be complete by mid-2022.

Once the all-important infrastructure is in place, BHP will look to initiate Stage I expansion at Mount Keith, increasing mining activity by 50 per cent.

The deployment of Liebherr 9600 and 9400 excavators will add to the cause, as the operation ramps up to its 15Mpta goal.

Haegel underscored the need for BHP and the world to give nickel such attention, as 2020 saw a 44 per cent increase in electric vehicle sales despite the pandemic.

It is expected that a quarter of all vehicle sales will be electric vehicles, and nickel will play a big part in supplying such demand.

BHP also aims to rebuild its furnace at the Kalgoorlie nickel smelter to account for the material coming from Mount Keith.

Additionally, BHP will look to exceed 100,000 tonnes per annum at the Kwinana nickel sulphate plant in an Australian-first and expected to be one of the world’s largest when operations begin.

The plant’s stage four commissioning began last week and first crystals are expected in the September quarter of 2021.

To conclude his presentation, Haegel introduced his successor in Jessica Farrell who will be taking over from Haegel after 6.5 years as asset president.

Short Link:

https://www.miningnews.ir/En/News/615203

The London Metal Exchange (LME) on Saturday banned from its system Russian metal produced on or after April 13 to comply ...

China’s state planner on Friday finalized a rule to set up a domestic coal production reserve system by 2027, aimed at ...

Chile’s SQM called another investors meeting at the request of its second-largest shareholder, Tianqi Lithium Corp., ...

French mining group Eramet said on Wednesday it had reached an agreement with the French government to continue its ...

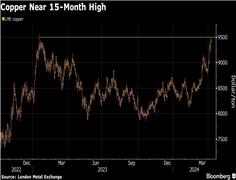

Copper traded near a 15-month high as supply concerns and brighter demand prospects triggered a slew of bullish calls on ...

Rare earths prices in top producer China jumped to their highest in more than seven weeks on Monday on a wave of ...

Copper jumped to its highest intraday price since January 2023 as the bellwether industrial metal faces rising tighter ...

A US and European Union push to reach an accord on fostering critical mineral supply chains is set to miss another ...

Indonesia’s mining minister on Wednesday said divestment of Vale Canada Ltd and Sumitomo Metal Mining Co. Ltd’s shares ...

No comments have been posted yet ...