- Write by:

-

Thursday, January 16, 2020 - 12:15:16 PM

-

571 Visit

-

Print

Mining News Pro - Annual cobalt production is only around 130,000 tonnes, mostly as a byproduct of nickel and copper mining. Some two-thirds of supply comes from the Democratic Republic of the Congo, where fears about political instability and the challenges of ethical sourcing combine to supercharge supply concerns.

Bloomberg reported Wednesday that Tesla is in talks to buy cobalt from Glencore for its third gigafactory, recently opened in Shanghai, according to people familiar with the matter. Tesla, alongside Google, Apple and others, were sued by a human rights group in December about artisanal cobalt mining in the Congo.

Neither the Swiss miner or the electric vehicle manufacturer, which is targeting production of 150,000 annual units in Shanghai would comment, but should the deal go through it would mark the fifth long-term supply deal made by Glencore over the past year.

In April, Glencore signed a deal with BMW to provide the German luxury vehicle company with cobalt from its Murrin Murrin mine in Australia.

Glencore also signed three other large, long term deals in 2019, with Korean battery manufacturer SK Innovation for 30,000 tonnes (enough to make 2m EVs with today’s cathode technology), Belgian chemicals giant Umicore and China’s GEM, a battery recycler.

Benchmark Mineral Intelligence, a battery supply chain and price reporting company, estimated that even before today’s report that the publicly announced agreements in 2019, alongside private deals, suggest that already “more than 80% of Glencore’s DRC cobalt hydroxide production will be locked up in long-term agreements.”

Price plunge

If the Glencore–Tesla deal happens it would leave precious little for the spot market in the coming years.

But so far, these developments and Glencore’s decision in August to halt operations at its Mutanda copper-cobalt mine in the Congo until at least 2021, have done very little to boost the market.

Considering that Mutanda is the world’s largest cobalt mine and responsible for a fifth of global output, the market response has been more than disappointing, with only a couple of months of rising prices.

Benchmark reports cobalt prices came under renewed pressure in December, most notably for cobalt hydroxide, which plunged by more than 10% over the course of the month.

Cobalt hydroxide is usually produced at mines as part of the primary processing of cobalt ores and typically contains 20-40% cobalt. The Asian import price of cobalt hydroxide was $20,800 per tonne (100% Co contained basis) at the end of the year, according to Benchmark data.

That constitutes a 47% drop in price over the last year and compares to price above $80,000 a tonne mid-2018:

The outlook for the short term is not rosy, and Benchmark predicts further weakness in the Chinese market during lunar new year celebrations.

Spot trading will reduce significantly due to the long delivery lead times from the Congo which is typically associated with falling prices, says Benchmark.

New energy

Another concern for cobalt bulls is weakness in China, responsible for every other EV sold around the world.

Changes to Chinese subsidies for hybrid and battery-powered vehicles – or new energy vehicles in local parlance – that came into effect mid-June had a dramatic impact on the domestic market.

Official figures released on Monday showed annual EV sales in 2019 dropping for the first time ever to 1.21m units, compared to 60% growth in the previous year.

Short Link:

https://www.miningnews.ir/En/News/473911

China’s state planner on Friday finalized a rule to set up a domestic coal production reserve system by 2027, aimed at ...

Chile’s SQM called another investors meeting at the request of its second-largest shareholder, Tianqi Lithium Corp., ...

Peru’s Las Bambas copper mine, owned by China’s MMG, is facing renewed blockades of a key transport route after failed ...

Vitol Group confirmed that it’s starting to rebuild a trading book for metals after a long stint out of the market, with ...

Chinese investors are snapping up stocks tied to high-flying metals from copper to gold, aiding an onshore market facing ...

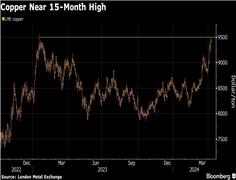

Copper traded near a 15-month high as supply concerns and brighter demand prospects triggered a slew of bullish calls on ...

Rare earths prices in top producer China jumped to their highest in more than seven weeks on Monday on a wave of ...

Copper jumped to its highest intraday price since January 2023 as the bellwether industrial metal faces rising tighter ...

Mining News Pro - Amir Khormishad, the CEO of the National Copper Industries Company of Iran, announced the 49% growth ...

No comments have been posted yet ...