- Write by:

-

Tuesday, June 16, 2020 - 10:38:32 AM

-

846 Visit

-

Print

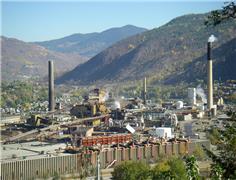

Mining News Pro - An innovative concept for a new mine (more accurately a large group of 55 small mines over the LOM) has been unveiled by Osisko Metals in the PEA for its Pine Point lead-zinc project located near the town of Hay River in the Northwest Territories, Canada, which will have an average annual production of 327 Mlb of zinc and 143 Mlb of lead making it a top ten global zinc producer.

Pine Point will be a large scale operation (11,250 t/d), where the mineral resource mined would be sourced mainly from multiple small, near-surface open pits with additional contributions from eight high grade, shallow deposits mined by underground methods from the West and Central Zones. There will be ~100 km of 25 m wide haul roads on site.

The open pit mineral resource inventory used in the LOM plan is contained in 47 open pits over a strike length of 50 km and is mainly located above 125 m depth from surface. Most of the deposits are characterised by multiple shallow tabular panels dipping approximately 2-5 degrees to the West. The open pit mining method incorporates 5 m benches in mineralised material, 10 m benches in waste and an overall open pit wall angle of 45 degrees. Mineral resources will be extracted using a fleet of long-haul trucks with a payload of 90 t. The production rate will vary between 8,000 t/d and 11,250 t/d. The strip ratio is expected to average 5.2 to 1.

Underground operations will use 45 t haul trucks with a ramp access to produce at a rate of 4,000 t/d in the West Zone and 1,500 tpd in the Central Zone. The mining methods used are a mixture of long hole stoping (80%) combined with room and pillar (20%). All mineral resources will be transported to a central concentrator located adjacent to the existing electrical substation. Additional power will be supplied by LNG fuelled generators.

The Pine Point process plant is designed to treat up to 11,250 t/d ROM material. The processing plant consists of a three-stage crushing circuit incorporated with an XRT based mineral sorting system that will reject 40% waste material on average. The mineral sorter concentrate will be blended with the crushing circuit fines to feed a ball mill (6,700 t/d) followed by conventional lead and zinc flotation circuits. The process plant will produce on average 168 t/d of lead concentrate at 62% Pb and 687 t/d of zinc concentrate at 58% Zn.

Concentrate would be hauled approximately 80 km by truck to the intersection of Highway 5 and 2 to a transloading facility at Pine Point Junction. Concentrate will be sent to North American smelters by railway, and further afield to Asian smelters by bulk sea freight.

The main electrical substation will feed 9 MW during the winter months and 12 MW during the summer. The power requirements will be provided by the Northwest Territories Power Corporation through the Taltson hydro-electric grid. The construction period is estimated to be 18 months long. Additional power will be supplied by mobile LNG fuelled generators that can be quickly moved to the various sites requiring power and minimising the amount of transmission lines needed as several open pit mines have a mine life of less than three years. Further studies will aim to optimise the number and capacity of these LNG power generation units.

Overburden stockpiles and waste rock stockpiles will be located nearby planned open pit mines where necessary and waste rock will also be deposited in former historical open pit mines. The overburden and waste rock will also be used for progressive reclamation where feasible. There will be no Tailings Management Facility as certain former open pits from the Cominco Ltd. era will be used for tailings disposal and then covered by pre-concentrator reject waste rock material and finally covered with coarser sterile waste rock.

Short Link:

https://www.miningnews.ir/En/News/548791

Zinc traded close to a one-year high as metals markets looked past delays to US monetary easing to focus on looming ...

Copper jumped to its highest intraday price since January 2023 as the bellwether industrial metal faces rising tighter ...

Canadian miner Teck Resources has agreed to pay Korea Zinc $165 per metric ton, a three-year low, to turn its zinc ...

Trading of CME Group Inc.’s nearly three-year-old lithium hydroxide futures contract is soaring, with more funds ...

NextSource Materials has submitted an application to build a downstream battery anode facility (BAF) to process graphite ...

Northvolt AB is starting construction of a €5 billion ($5.4 billion) battery plant in northern Germany to supply ...

Iron ore futures tumbled in Singapore, extending a stretch of volatile trading amid deepening anxiety over Chinese ...

Copper and zinc miner Teck Resources is considering building a lithium-ion battery recycling facility in British ...

Australia’s Perseus Mining is not giving up on its plans to acquire African gold developer OreCorp, releasing on Friday ...

No comments have been posted yet ...