- Write by:

-

Tuesday, November 20, 2018 - 2:46:28 PM

-

1452 Visit

-

Print

Mining News Pro - Mohammad Reza Ghasemi, referring to the conclusion of the contract with Kani Copas, said: "The equipment needed to create the necessary ground for the start of geotechnical studies has begun, and in the lead week we will begin to conduct the implementation of geotechnical engineering studies and hydrology."

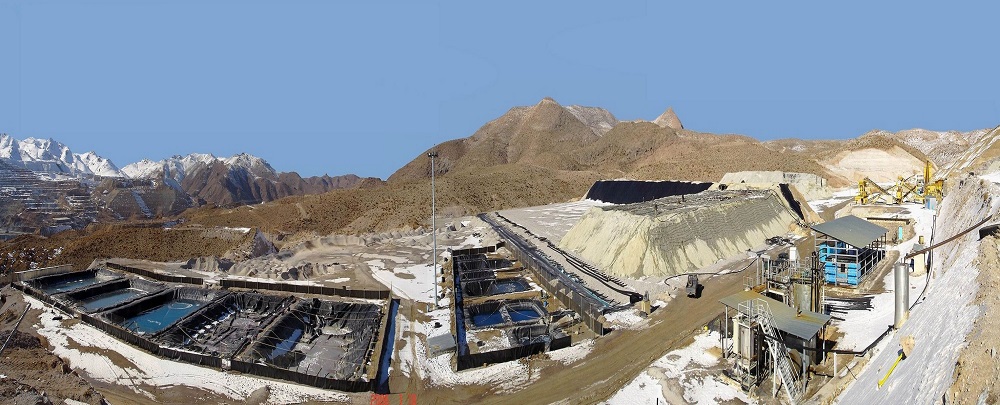

According to Mining News Pro -Mohammad Reza Ghassemi, director of the Heong Leaching Project, said that the Heap leaching project started in an area of 80 hectares in the Sungun Copper Complex, which is one of the major mining concerns that is the debate about the depoorous rocks and the occupation of a high volume of work space. The goal of this project is to convert minerals to the total of 99.99% of copper, which, with its implementation, in addition to generating a new product (99.79% copper cathode), is a matter of concern over decomposing gems. Time will be resolved.

He added that the use of the Flotation method for this project is not cost-effective and causes some technical problems.

Ghasemi continued, "The main focus of the Copper Corporation is respect for environmental principles, given the emphasis of Copper Copper Management and Sungun Copper Management, on the basis of which the motto of clean industry and sustainable production can be realized."

Referring to the pursuit of legal affairs of the complex and the creation of work arrangements, such as coordination with natural resources and land ownership, he added: "Fortunately, initial work has been done and according to planned plans, the implementation of this project will take 28 months, and after this period the project will be attended by The contractor will be loaded and exploited for a period of four months.

The head of the Heong Leaching project, Sungun, pointing to the use of the acid washing method in the plan, added: "The feed capacity of the plan will be 2 million tons of ore mineral with a grade of 0.3 percent annually, and the annual production of 3 thousand tons of cathode copper is 99.99. Launching and passing time will increase production.

Qasemi, referring to the investments made and the allocation of necessary rials and foreign exchange, said: using this project, 80 people will be directly employed and 150 will be indirectly created.

Project supervisor Heong Leaching said: "Fortunately, with the necessary follow-ups, we have been sampling 25 million tons of existing crude rock (deposed) and are equipping the laboratory for pilot testing."

Referring to the completion of the mapping and topographic operations of the site, as well as the process steps, he continued: As mentioned, the acid-washing process will be used in this project, and in the technology used, the acids and organic materials used after the operation to the production cycle Which means increasing the efficiency and lowering the final product price.

Short Link:

https://www.miningnews.ir/En/News/301841

Australian miner Lynas posted a slump in third-quarter sales revenue on Wednesday, missing analyst expectations on the ...

Zimbabwe’s President Emmerson Mnangagwa has re-appointed Winston Chitando as the southern African nation’s mines ...

Anglo American Plc said it is has received an unsolicited non-binding combination proposal from BHP Group.

China’s Zhaojin Mining Industry said on Wednesday that its A$733 million ($477.8 million) offer to buy Australia’s ...

Toronto-listed miner OceanaGold Corp said on Wednesday it will raise 6.08 billion pesos ($106 million) through an ...

A key measure of Chinese copper demand just sank to zero, another indication that global prices are not balanced with ...

A new report by IDTechEx states that investing in e-haul trucks could result in major savings for miners due to the ...

Chile’s state copper company Codelco defended its proposed lithium production tie-up with SQM in response to criticism ...

Canadian miner First Quantum Minerals (TSX: FM) believes it will be able to take the already mined 121,000 tonnes of ...

No comments have been posted yet ...