- Write by:

-

Thursday, November 8, 2018 - 4:17:04 PM

-

897 Visit

-

Print

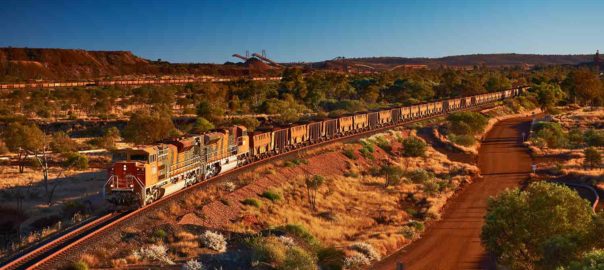

Mining News Pro - Caterpillar has quickly become a leader in the field of autonomous haulage, with many new and retrofitted solutions found across Western Australia and the Canadian oil sands.

According to Mining News Pro -Caterpillar has quickly become a leader in the field of autonomous haulage, with many new and retrofitted solutions found across Western Australia and the Canadian oil sands.

Yet, the company is not slowing down now it has passed more than 100 operating in the field, with its scalability lab – part of the virtual mine site at the company’s Mossville facility in Peoria, Illinois – a key driver in achieving more sales.

This lab has been in place for more than five years and was devised to stay 20-25% ahead of Cat’s biggest Command for hauling customer, IM and other mining journalists were told on Wednesday during a tour of the facility.

From this lab, and its array of monitors, operators track and orchestrate the movement of hundreds of vehicles, with controllers setting daily production goals and sending machines for maintenance or diagnostic testing. It is designed to enact a real mine site, with the simulation running 24 hours a day, five days a week.

The 20-25% goal means the company is now simulating some 400 pieces of manned and unmanned equipment using Command for hauling in its lab. It uses real-life operating data previously collected from its customers as input parameters, while having set ‘scripts’ for the operating behaviour of the equipment.

The virtual equipment currently includes some 120 autonomous haul trucks, 30 manned trucks and over 100 auxiliary vehicles.

The ability to simulate this mass of machines ensures Caterpillar stays ahead of the game.

In addition to this, the company can use a nearby test track to simulate the reaction time, hazard perception and general behaviour of autonomous trucks via fully kitted out Chevrolet Tahoes. The Tahoes are set up with components normally found on mining equipment in the field, with the generated data scaled up to the equivalent of one of its, or another vendor’s, haul trucks.

All this R&D means the company can continue with its ambitious programme of releasing two new updates of Command for hauling every year with several valuable additions.

It also allows the company to test out some 90-95% of Command for hauling functionality before it even gets to the machines operating at the company’s Tinaja proving grounds in in Tucson, Arizona.

Short Link:

https://www.miningnews.ir/En/News/293618

Mining News Pro - In the difficult and exhausting conditions of unilateral and cowardly sanctions, more than any other ...

Mining News Pro - The CEO of Khuzestan Steel Company informed about the plans made to reach the production level of 13 ...

Mining News Pro - The 19th International Metallurgy Exhibition (IranMetafo) was held at the permanent location of Tehran ...

Mining News Pro - European Commission President Ursula von der Leyen said last month that commodities like lithium and ...

Mining News Pro - In response to Western sanctions, Russian miners have looked towards merging to create companies ...

Mining News Pro - In 2020, Iran started to promote mining tourism by launching the first project in the Anguran lead and ...

Mining News Pro - Acid mine drainage has long been a scourge in Appalachia. Recent research suggests that we may be able ...

Mining News Pro - Using a global data set of zircon trace elements, new research demonstrates the power of machine ...

Mining News Pro - The global markets of nickel, lithium and cobalt – three of the key metals used in electric vehicle ...

No comments have been posted yet ...